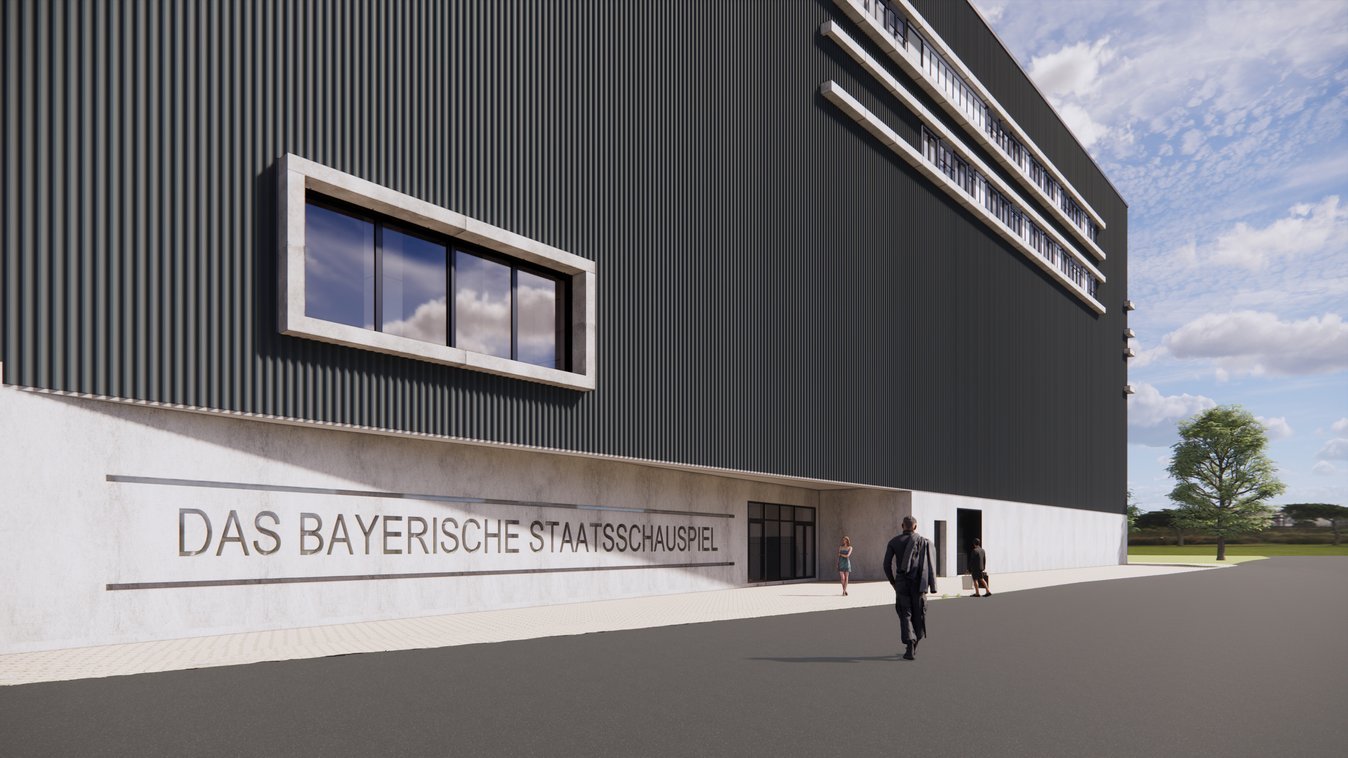

PWZ Proben- und Werkstättenzentrum

Short description

BBV Systems is adding its expertise to this joint project involving many Implenia units.

The project

This complex and technically demanding project requires tendons, for example to make the entrance to the underground garage column-free. But also to ensure the high and open spaces for the rehearsal stages. Both during construction and in the final state.

Thanks to their improved load-bearing capacity, tendons can also be used to construct slabs with smaller quantities of slack reinforcement and concrete, which saves costs and resources.

The tendons are prefabricated in our factory in Bobenheim-Roxheim, delivered to the construction site and can then be installed quickly and efficiently on site. Just one week after the slab has been concreted, the tendons are prestressed to the required strength, thus establishing the load-bearing capacity of the slab areas.

Services in detail

Tendons in the basement to 4th floor

- Approx. 15.5 tons of prestressing steel

- 182 Lo6 stressing anchors

- 182 Lo6 fixed anchors

- 12 Lo4 stressing anchors

- 12 Lo4 fixed anchors

Challenges

Short planning times, resulting in a high need for coordination with all companies involved. From plan handover to delivery of the tendons in just a few weeks.

Sustainability

The building is constructed in accordance with the Building Energy Act (GEG § 10), all materials comply with the requirements catalog "Low-pollutant construction" (QN 3) of the Bavarian State Building Directorate and the technical systems are designed for sustainable and environmentally friendly operation